the brinell hardness test wikipedia|brinell hardness test formula : agencies The Brinell scale is a measure of hardness in materials. It is measured by making a dent in the material and seeing how deep the dent goes with a known amount of force. It is similar to the . 15 horas atrás · 最佳回答 “"又又酱新年定制2020视频背后的故事"” 三一国际盘中异动 股价大涨5.12% 2024年02"又又酱新年定制2020视频背后的故事"月29日下午盘14时39分,三一国际(00631.hk)股票出现异动,股价急速 资金方面,该股 .

{plog:ftitle_list}

webAbsolutamente. Nuestro sitio tiene miles de tragamonedas gratis con bonos y giros gratis. Nuestros mejores juegos de tragamonedas de casino gratis con rondas de bonificación .

August Brinell (19 June 1849 – 17 November 1925) was a Swedish Metallurgical Engineer. Brinell is noted as the creator of method for quantifying the surface hardness of materials, . A variety of hardness-testing methods are available, including the Vickers, Brinell, .2. Brinell Hardness Test. The Brinell test uses a larger spherical indenter, usually made of steel or carbide, and applies a heavy load to the material. The diameter of the indentation is .The Brinell scale is a measure of hardness in materials. It is measured by making a dent in the material and seeing how deep the dent goes with a known amount of force. It is similar to the .

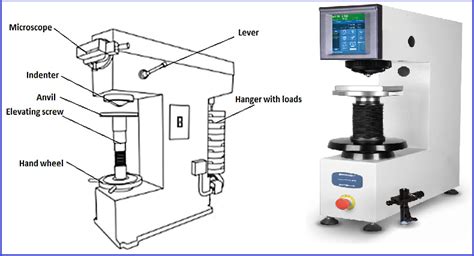

Brinell test procedure. In the Brinell hardness test, an optical method, the size of indentation left by the indenter is measured. In contrast to the likewise optical Vickers method,which involves .The oldest of the hardness test methods in common use on engineering materials today is the Brinell hardness test. Dr. J. A. Brinell invented this test in Sweden in 1900. The Brinell test .The Brinell hardness test method as used to determine Brinell hardness, is defined in ASTM E10. Most commonly it is used to test materials that have a structure that is too coarse or that have a surface that is too rough to be tested . Vickers hardness (MPa) [1] Brinell hardness (MPa) [1] Brinell hardness (MPa) [note 1] [2] 3: Li: lithium: 0.6 ~2: 5: 4: Be: beryllium: 5.5: 1,670: 590–1,320: 5: B: boron: 9.3 [3] .

Notice that the Brinell test can report the same hardness value for a given specimen twice depending on the load. The Meyer hardness test is a hardness test based upon projected area of an impression. The hardness, , is defined as the maximum load, divided by the projected area of the indent, . [1] =.布氏硬度试验(Brinell scale)是压入硬度试验之一种,其测量值用HB或BHN表示。. 该试验最初由瑞典 工程师 Johan August Brinell(1849年-1925年)于1900年提出。 布氏硬度是第一个被广泛用于工程学及冶金学的标准化硬度试验。 此试验方法因压痕较大和对待测材料损伤明显,应用受到 .The Barcol hardness test characterizes the indentation hardness of materials through the depth of penetration of an indentor, loaded on a material sample and compared to the penetration in a reference material. The method is most often used for composite materials such as reinforced thermosetting resins or to determine how much a resin or plastic has cured.A variety of hardness-testing methods are available, including the Vickers, Brinell, Rockwell, Meyer and Leeb tests. Although it is impossible in many cases to give an exact conversion, it is possible to give an approximate material-specific comparison table for steels .

Tvrdost podle Brinella se označuje akronymem HB (Brinell hardness). Jestliže je pro měření použita kulička z kalené oceli, označuje se metoda ve zkratce HBS. Ta je vhodná pro měkčí materiály. Je-li třeba měřit materiály větší tvrdosti, pak se použije kulička ze slinutých karbidů, označení takové zkoušky je potom HBW .The hardness of abrasion resistant steel is determined by a Brinell hardness test. This test uses a small steel ball to inflict force on a material. . Average Brinell Hardness Numbers (BHNs) for Abrasion Resistant Steel Grades [4] Grade BHN AR200 & AR235: 180-260 AR400: 360-440 AR450: 430-480 AR500: 460-544 AR600: 570-625

A Vickers hardness tester. The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. [1] The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter .“EN ISO 6506-3:2014: Metallic materials – Brinell hardness test – Part 3: calibration of reference blocks”. “EN ISO 6506-4:2014: Metallic materials – Brinell hardness test – Part 4: Table of hardness values”. Tiêu chuẩn Mỹ (ASTM Quốc tế) “ASTM E10-14: Standard method for Brinell hardness of metallic materials”.Uji kekerasan Brinell (Brinell hardness test) adalah sebuah pengujian kekerasan terhadap suatu bahan: Dalam tes ini, sebuah bola baja berdiameter tertentu diletakkan di atas bahan yang sedang diuji, lalu dikenakan suatu beban. Hasil dari pengujian ini adalah bilangan kekerasan Brinell, yang tergantung besarnya jejak yang terbentuk pada bahan . English: Brinell Hardness Test. Nederlands: Brinell-hardheidstest. Date: 16 April 2009, 20:05 (UTC) Source: BrinellSkizze.jpg; Author: BrinellSkizze.jpg: Lokilech; derivative work: Nerdture (talk) This is a retouched picture, which means that it has been digitally altered from its original version.

Additionally, the pages linked to the standards are wrong. I tried following the standard EN ISO 6506-1:2005: Metallic materials – Brinell hardness test – Part 1: test method and it was linked to a Vickers (NOT Brinell) standard (also withdrawn) — Preceding unsigned comment added by 79.136.68.68 10:56, 24 January 2019 (UTC)Meyer's law is an empirical relation between the size of a hardness test indentation and the load required to leave the indentation. [1] The formula was devised by Eugene Meyer of the Materials Testing Laboratory at the Imperial School of Technology, Charlottenburg, Germany, circa .Category: Brinell hardness test. Da Wikimedia Commons, l'archivio di file multimediali liberi. Vai alla navigazione Vai alla ricerca scala di Brinell scala di valori ricavati dalla prova di durezza dei materiali con il metodo Brinell, ideata dal metallurgista svedese Johan August Brinell. Carica un file multimediale Wikipedia. Istanza di .

Angles of a Knoop hardness test indenter. The Knoop hardness test / k ə ˈ n uː p / is a microhardness test – a test for mechanical hardness used particularly for very brittle materials or thin sheets, where only a small indentation may be made for testing purposes. A pyramidal diamond point is pressed into the polished surface of the test material with a known (often 100 .Brinell hardness test (HB) BHN and HBW are widely used [7] Knoop hardness test (HK), for measurement over small areas, widely used to test glass or ceramic material. [8] Janka hardness test, for wood; Meyer hardness test; Rockwell hardness test (HR), principally used in the USA. HRA, HRB and HRC scales are most widely used.ブリネル硬さ(ブリネルかたさ、英: Brinell hardness )は、工業材料の硬さを表す尺度の一つであり、押込み硬さの一種である。 記号はHB(Brinell hardness number=BHNも使われるが、HBの方が一般的)。. 試験法は1900年にスウェーデンの工学者であるヨハン・ブリネル(Johan August Brinell)により考え出さ .

A Rockwell hardness tester. The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the .'n Kragtediagram wat die kragte en afmetings vir 'n Brinell hardheidstoets aantoon. Die Brinell-skaal word gekenmerk aan die inkepingshardheid van materiale deur die penetrasievermoë van 'n inkeper wat gelaai word op 'n materiaal toetsstuk. Dit is een van verskeie definisies vir hardheid in materiaalkunde en sterkteleer.. Hierdie metode is oorspronklik voorgestel deur 'n Sweedse .Brinellprov. Brinellskala är ett mått på ett materials hårdhet som bestäms med en metod uppfunnen av Johan August Brinell, överingenjör vid Fagersta Bruks AB.Metoden som presenterades vid världsutställningen 1900 i Paris lämpar sig för mjuka och medelhårda material. Principen går ut på att mäta ett materials förmåga att motstå plastisk deformation, precis som .In materials science, hardness (antonym: softness) is a measure of the resistance to localized plastic deformation, such as an indentation (over an area) or a scratch (linear), induced mechanically either by pressing or abrasion.In general, different materials differ in their hardness; for example hard metals such as titanium and beryllium are harder than soft metals such as .

q-pert

布氏硬度试验(Brinell scale)是压入硬度试验之一种,其测量值用HB或BHN表示。. 该试验最初由瑞典 工程师 Johan August Brinell(1849年-1925年)于1900年提出。 布氏硬度是第一个被广泛用于工程学及冶金学的标准化硬度试验。 此试验方法因压痕较大和对待测材料损伤明显,应用受到 .The steady-state wear equation was proposed as: [2] = where is the Brinell hardness expressed as Pascals, is the volumetric loss, is the normal load, and is the sliding distance. is the dimensionless standard wear coefficient. . Therefore, the wear coefficient in the abrasive model is defined as: [2]. =. As can be estimated from weight loss and the density , the wear ."EN ISO 6506-2:2017: Metallic materials – Brinell hardness test – Part 2: verification and calibration of testing machine". "EN ISO 6506-3:2014: Metallic materials – Brinell hardness test – Part 3: calibration of reference blocks". "EN ISO 6506-4:2014: Metallic materials – Brinell hardness test – Part 4: Table of hardness values".

Vickers hardness tester Wiki 90 JS is a microhardness testing machine with test loads from 0,001 to 62,5 kgf. This hardness tester is suitable to test Micro Vickers, Macro Vickers, Knoop, and Brinell hardness test scales. Wiki 90 JS is conformed to all hardness standards including ASTM and ISO.Two inline skate wheels with different durometer – 85A and 83A Digital Shore hardness tester. The Shore durometer is a device for measuring the hardness of a material, typically of polymers. [1]Higher numbers on the scale indicate a greater resistance to indentation and thus harder materials. Lower numbers indicate less resistance and softer materials.

Vickers Hardness Test Wikipedia. The first reference to the. the vickers hardness test was developed in 1921 by robert l. the vickers test has a great advantage of using one hardness scale to test all materials. . standardized optical hardness testing methods include the brinell hardness test (iso 6506, astm e10), knoop hardness .What material and shape is the indenter for the Meyer hardness test ? .

brinell hardness tester

brinell hardness test standard

brinell hardness test procedure

Explore short and medium-term Cowabunga Coin price prediction analysis and check long-term Cowabunga Coin forecasts for 2025, 2030, and beyond 📈 🤖 🚀 Our algorithm is still .

the brinell hardness test wikipedia|brinell hardness test formula